Italian technology for the reconstruction of Notre-Dame

The reconstruction of Notre-Dame Cathedral in Paris has been one of the most important and complex cultural and architectural challenges of our time. After the devastating fire on April 15, 2019, France launched an ambitious restoration plan with the aim of returning one of the most iconic symbols of European history to the world within just five years. A decisive contribution, entirely Italian, came from MiCROTEC, a South Tyrolean company and world leader in scanning and diagnostic technology for the wood industry, which was acquired by Clessidra Private Equity in April 2025.

Founded in 1980 in Bressanone, MiCROTEC is present in over 50 countries and is a world leader in the supply of high-tech systems for wood diagnostics. The company combines computerized tomography, artificial intelligence, and hyperspectral imaging to create solutions for wood scanning, a technology that maximizes economic yield and minimizes environmental impact by almost completely eliminating waste..

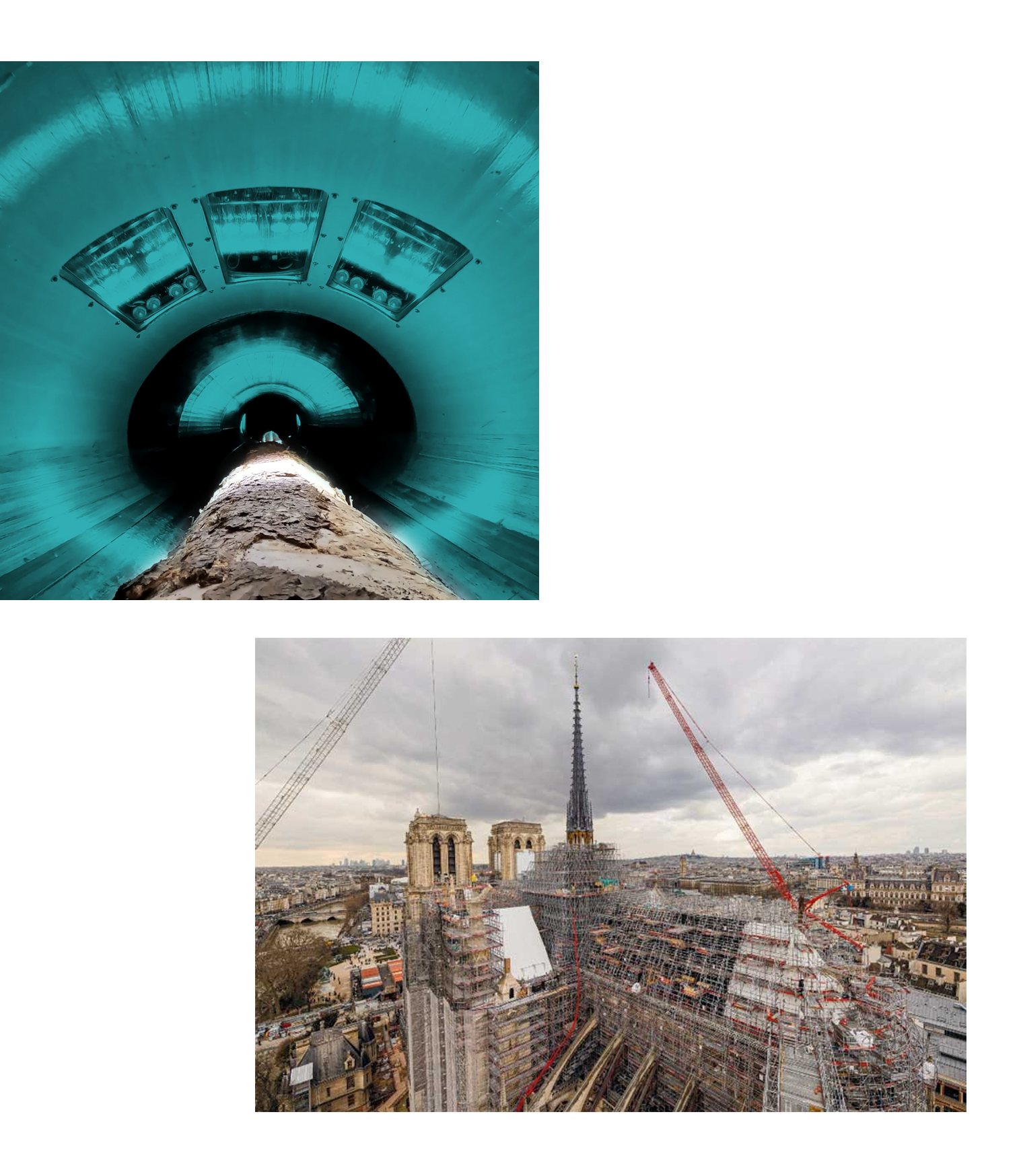

MiCROTEC's involvement in the reconstruction of Notre-Dame stems from the need to ensure precision and efficiency in the selection and use of the centuries-old oak trees used to rebuild the cathedral's famous spire, designed by architect Viollet-le-Duc in the 19th century and completely destroyed in the fire. Standing 93 meters high, the spire was built with over 500 tons of wood from 1,300 centuries-old oak trees, an extremely precious and limited natural heritage.

To address the delicate issue of sustainability, the Office National des Forêts, the body responsible for managing and safeguarding France's forest heritage, chose the Bressanone-based company, one of the very few non-French companies directly involved in the project. MiCROTEC's know-how was fundamental both in selecting the trees to be used and in minimizing waste during the cutting phase. Using detailed images acquired with drones, MiCROTEC created high-precision digital 3D models of the trees in the forest in order to select the most suitable ones. MiCROTEC's technologies also made it possible to create virtual models of the beams to be used, determining with extreme precision the ideal cutting position within the trunk. This was a crucial step in maximizing yield and minimizing material waste. The process, carried out virtually before physical cutting, allowed French forestry technicians to make informed and sustainable decisions, significantly reducing the project's environmental impact.

Participating in the reconstruction of Notre-Dame Cathedral was not only a technological and environmental success, but also a milestone for the company: contributing to the rebirth of a symbol of world cultural heritage has strengthened the pride and sense of belonging of all MiCROTEC employees worldwide.

The success of such an ambitious and complex project demonstrates how technology, sustainability, and cultural heritage can be effectively combined to address some of the most complex and sensitive challenges of our time.